Hello

Great Topic you started Tom,I really like your approach,it's fun to see what people from different backgrounds bring to Rod Making. By now I've met rod tinkers from just about every walk of life.

It's amazing when - a Plumber,a Carpenter Boat Builder,a Professor,a Prosecutor,a Chemist,a Judge,a Trout Bum,a Metallurgist,a Archeologist,a Whom Ever - all have fishing and rod tinkering in common.

It's one of the things I learned as a young kid sitting around the camp fire with my Dad and his pals.

From the early age of 8 until about 12,Tinkered up my first 6 rods,back then Used a stack of books for tension,McClains was the foundation,a discarded double edged Razor blade,a Tea cup to keep the spool of thread from rolling across the floor,Scotch tape,a red pencil for guide spacing and placement,Moms Yard stick,a spool of Twine,10 cent paint brushes from the drug store,whatever Varnish or other stuff like sand paper I could scrounge from the boat house,head cement,plyabond cement,lots of plyabond.

When I was 13 Mom and Dad gave me a Herters Rod building kit for my birthday, The kit came with a thread tension device,thread,color preserver or should I say "color fixative",Rod Varnish, some other small hand tools,brushes,a pamphlet how to wrap a rod,The Rod Blank was a 7' Herters Spinning rod with a assortment of guides and tip tops,Also was gifted a copy of George Herters book with

.

"The Secrets Of Fishing Rods and How Fishing Rods Are Made".The Most Important Rod Making Tools I Have Ever Owned Period.

That was it from that point on the obsession had it's foundation,some kids hung around the pool halls,I hung around the tackle shops,and rod shops.

Spent the last 4 days getting stuff together to sell off,I'm going to the C.F.F.A. Expo this coming Saturday.

Really went deep into my rod quiver this time,also my hoard of materials.

I'm ashamed to say that some of my stuff had to be thrown out,also some of the stuff I had no recollection of,it was like seeing some stuff for the first time.

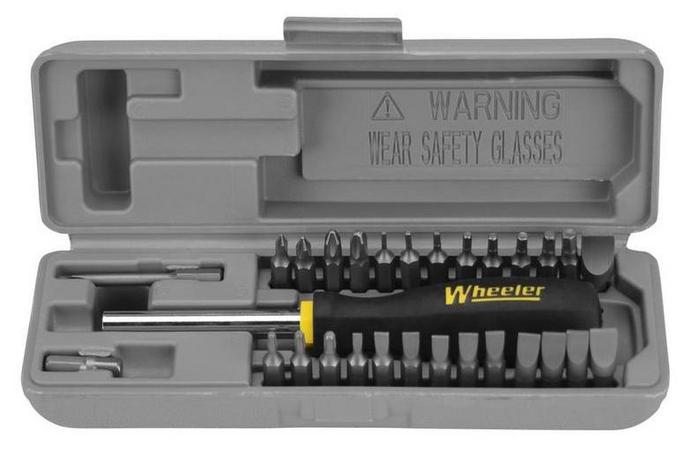

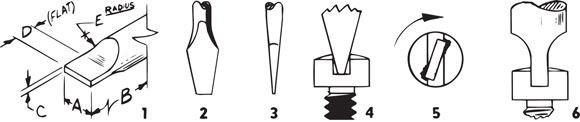

Anyhow I took some pictures to share with you here of some Rod Shop Goodies.

Tight Lines And Keep It Simple Loops

Andy M

Could Only Save The Label Mice Ruined The Box.

Ferrule Sizing Gauge,Large Spool Thread Storage Box.

Great To Keep On Hand.

Silk Thread Storage.

More Thread Storage.

Loaded Syringes Of L.S. Supreme

I was only kidding when I commented that my mixes are formulated by color.

The epoxy mixture methods I use will remain my secret.

My recommendation however is to always follow the manufactures recommendations/instructions,If you have a problem/issue the best course of action is to call/contact the manufacturer,they always have technical help experts on hand to assist you.They can also possibly give you some tips to get the best results using their products.

One of my rod racks got left out in the Car Port,it was looking weathered,I have a couple of cases left of the 1970's Rod Spray On Epoxy,Wouldn't Dream of using it on a rod but when it came to a rod rack why not right.

Well I gotta tell you the stuff went on slicker than grease and looks amazing.

When this stuff cures in 5 Min it's as the can says hard as nails.

Plastic Thread Carousel.

That's All For Now Folks.