I just finished making a 6'8" one-piece #4 solid wood rod.

Pics of the finished rod can be viewed here:

viewtopic.php?f=8&t=67795This thread will be a photo documentation of the build process, for those who are interested.

After some research, I settled upon using American Beech as the wood species.

Beech trees are identifiable by their very sooth, grey bark; and also in Winter they retain their yellow-tan leaves, and exhibit brown-reddish pointed "shoots" on the ends of their twigs:

A harvested young Beech tree trunk. Early-on I was advised to not use the center of the trunk (the "pith"?) as this isn't strong-grained material. So the target size was a tree small enough to easily work with, but large enough in diameter to split a usable section from the "good part" of the tree - about 3" caliper. Also selected for straightness and limited branches/knots in the trunk, as these will affect strength of the fly rod blank:

First step: get the bark off the wood.

Here is a comparison of a natural Beech trunk next to one stripped of its bark:

Next step: split the trunk into a length that is at least 1.5" in diameter, considering the handle and reel seat would be carved from this solid length, and there is a fair amount of "waste" to be accounted for while planing-off the material to get down to a straight, tapered blank:

Then the rough-planing begins. I clamped the gnarly split length down on my workbench and carefully planed it down, rotating it around incrementally as I worked, always trying to keep the result "straight" (not easy!)

That's a LOT of shavings! Next time I won't be so conservative, and may split a bit thinner raw blank to start with:

Tapering down:

The formation of a rough handle and reel seat:

Taper:

I used the hexrod.net “taper generator”. Because this was my first wood rod, and I wanted to stay conservative, I opted for a “straight” taper thinking it would produce the most uniform stress on the blank under load. Also being conservative and fearful of breakage, I started with the largest tip diameter I could also purchase a tip top that would fit (size 7.5 or .115” ). From there, I used that .115” tip as a starting point (and constant) to generate the taper. The other variable in hexrod is the “Rod taper in 1/1000-ths per linear unit:” I started conservatively with a 4.5 value which produces a med-fast taper in a bamboo hex rod. I taped-on some guides and test-cast. The rod was too stiff for my liking with this 4.5 value, So I sanded the blank down some more using a 4.25 value. Still too stiff. After some more trial-and-error I finally settled on 3.75. With its relatively thick tip the final action is “semi-parabolic” which I am quite happy with. With hexrod being geared toward bamboo, using it became only a loose guide to achive the lineweight and action I desired. A lot of trial and error and careful sanding was required to get what I wanted.

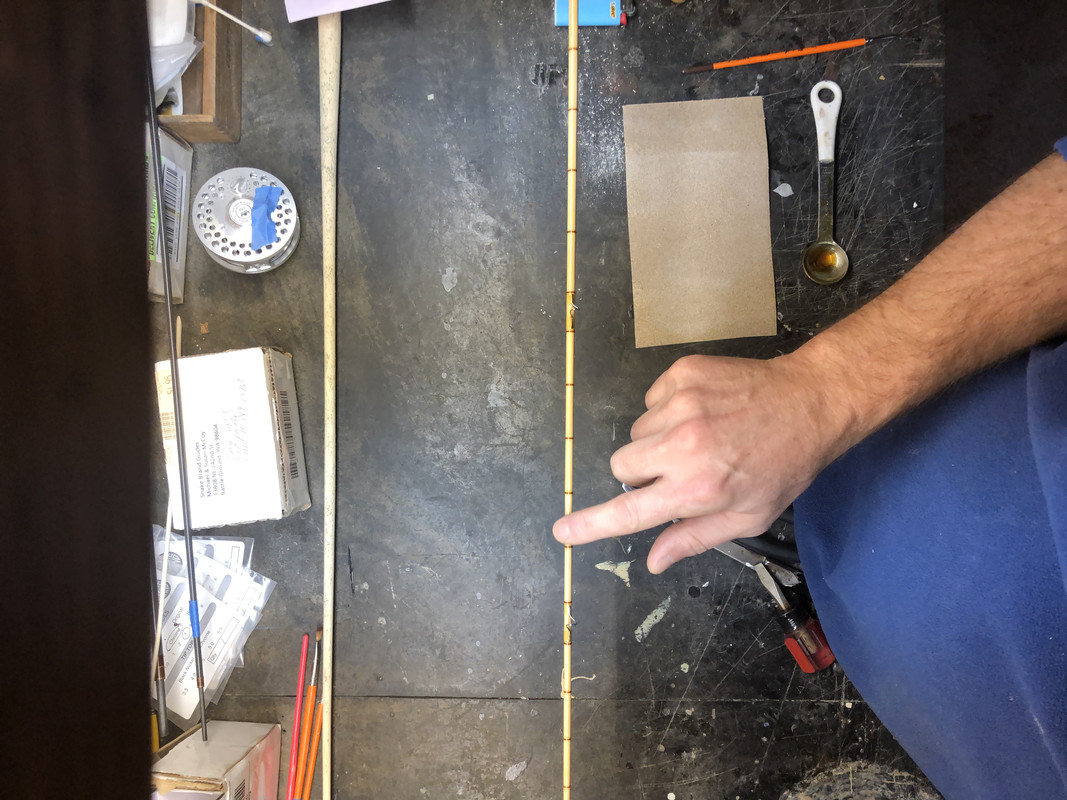

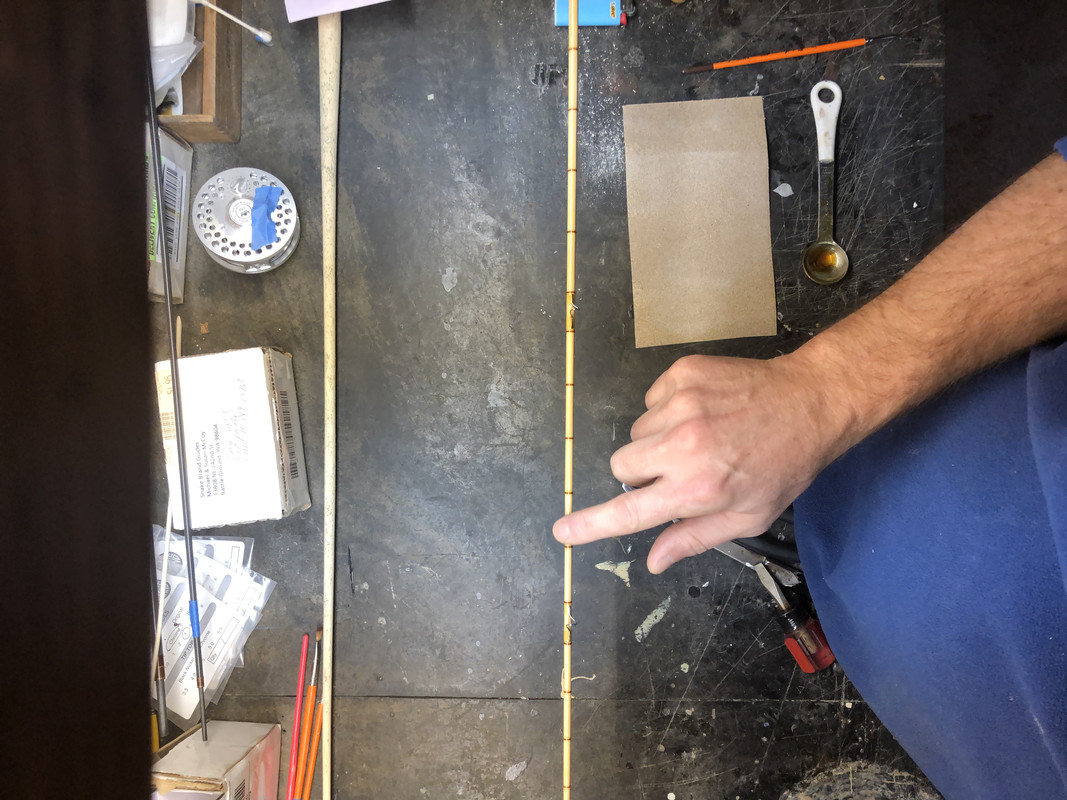

Eventually, once I got within .2"-.3" or so of final taper, then it was sandpaper and/or scraping with an x-acto blade to work down to final taper, and to carve-in a recess in the handle to accept the rattan grip, and mortise the bottom of the reel seat:

Along the way, the taper was checked by taping-on guides and test-casting. I started off pretty conservatively, keenly concerned about strength of the material and hazards of taking a set or even breaking. So the tip was set at .115" - the largest diameter i could get a fly tip-top for, or size 7.5. Early tapers were too stiff/fast, so I successively re-calculated the taper via hexrod.net and reduced material (moreso from the but-end) to achieve a slower taper with a lot better "soul".

once I was satisfied with the taper, at this point, the blank was treated with pure Tung Oil diluted with Artist's turpentine. Three penetrating coats.

End-grain at the butt end:

Deer Antler source material for the butt-cap:

Silk guide wraps were finished in Spar Varnish 4 thin coats.:

And the blank was final-finished with finger-applied Tru Oil, 3 thin coats:

The nearly-finished rod, next to a raw Beech trunk like I started with:

This was a very time-consuming, but fun and educational project. I am pretty happy with it.

I still have that other raw Beech trunk lying around, and may just go ahead and make another.