Hello

Gene as you know ferrule repairs are always a challenge that never changes especially when it comes to graphite.

Honestly most of the manufactures shy away from any type of broken shaft repairs, most often they just replace the rod with another or in some rare cases replace the broken section.

Many times if the break is not covered under their warranty they will offer a decent price reduction toward a new rod provided you are the registered original owner.

I had a sage come in a few months ago, when I saw the shape the tube was in I was afraid to open it. The rod a 9' 2/1 6wt was broken in 2 places with about 24" completely missing.

The reel seat looked like it was used as a golfing driver, anyway when I asked the guy if he had contacted sage to see if the rod was under warranty he laughed.

I asked seriously did you purchase the rod new and did you send in the card he answered yes.

Next we went on eBay and sure enough we found the exact same model rod for sale I think the bid was at like 50 beans with a few days to go.

The rod was in poor shape but full length.

We talked over the diss advantages of purchasing the eBay rod and then me doing the necessary tune up to get it in decent shape for fishing?

We decided that if the rod went for under 100 beans we would roll the dice.

In the meantime I suggested that I should contact sage with the serial number etc and find out

If the rod was covered.

The next morning I called gunner at sage with the information he looked up the number and said well yes and no, the rod was covered but since the rod model was so very old and by the description I gave him he could only make the call naturally after the rod was sent to him for evaluation.

However for a nominal fee he could either replace the rod with a discontinued comparable model

Of lesser value than the original or a more current blank of equal value.

This all naturally hinged on his receiving the rod at sage for evaluation and the rod being worthy of being considered broken under the guidelines of the original warranty.

I passed the information on to the rods owner and we waited for the auction to end, during the course of the auction another one came up for sale so we added it to the watch list yep you guessed it another one surfaced so we added it to the watch list, well that went on for about 2 weeks none of them were at or below our set limit.

Next I packed up the rod enclosed a check for the return shipping, the nominal fee for the new blank should the rod be considered covered, a note with all the pertinent information etc, it was at a very bad time to send it during the pre holiday season early november, I sent it parcel post with insurance and delivery confirmation it took 13 days for it to make the cross country journey it only took me 6 days hitch hiking back in 75 but that's another story ha ha.

So we patiently waited every now and then I checked to see if the check had been cashed, finally it had so I called gunner he said according to his paperwork the rods evaluation was complete and a new blank would be shipped in the next few days.

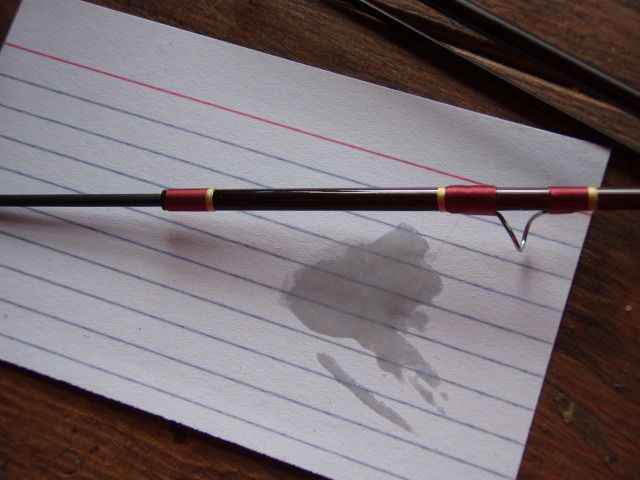

Gunner and the staff at sage are truly devoted to their customers the blank arrived last week it's first rate all the way! , they also returned the broken rod so I could salvage the hardware the winding check, hook keeper, stripping guides now I just have to convince the owner to let me

Use a new reel seat as he really wants me to salvage the old one.

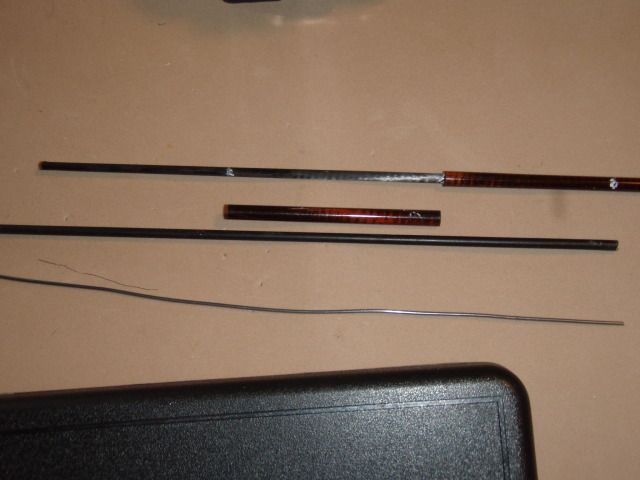

The reasons I went into this are to emphasize that some graphite rods actually most rods can be restored with used donor rod parts , that's why rod repair folks have so many broken rods that just seem to languish, gene certainly proved that who else would of had a matching section for his repair!

If you don't have what you need the next best thing is to ask if anyone else has what you need as gene did as well.

Bamboo rod sections often get traded between tinkers, when those avenues fail eBay is a great source you may have to wait but eventually they do seem to show up.

Last but certainly not least the first thing you should always do is contact the rod manufacturer directly to see what they are willing to do for you.

Anyway back to the topic sorry for the rant gene.

As I often hear their is more than one way to skin a cat at least that's what people say I wouldn't know I've never actually had the need or desire to skin one ha ha

Seriously everyone has their own methods of tackling rod repairs, god only knows in the beginning I had enough of mine fail, but every time we do one we learn more, now with the aid of the internet we can actually learn from each others mistakes and accomplishments!

Tight lines and always challenging loops

Andy M

any chance you'll pay to do the repairs gene if so whats the current rate your paying?

any chance you'll pay to do the repairs gene if so whats the current rate your paying?