not exactly true - taper is change in bulk modulus over length.

Bulk modulus is the specific modulus (of the blend) multiplied by the moment of inertia, which is geometric, dependent on diameter and thickness. Of course, adding thickness adds weight, but it also adds stiffness, while increasing diameter can add stiffness without significantly increasing weight.

Rods are built on mandrels that define the inside diameter of the taper.

Specific modulus (or equivalent) of the MOCs increases as follows: e-glass, s-glass (equivalent to cane), and whole gang of graphites, from I to V.

The MOI math is how you design a spigot ferrule that bends at the correct rate for its position on the rod taper.

You can make any taper from e-glass, demonstrated by great big game rods. With higher modulus, you're limited how soft you can go by strength.

If you look at old Heddon T tapers in e-glass, they have a super-soft 1' tip, but the rest of the rod is quite fast - that's a superprogressive taper.

At the other extreme are parabolic tapers, where the tip is fast and most of the flex is closer to the handle (how you make a short rod cast with a long rod).

You find superprogressive tapers (fine tip) used in a lot of early glass spinning rods and bait rods (Silaflex).

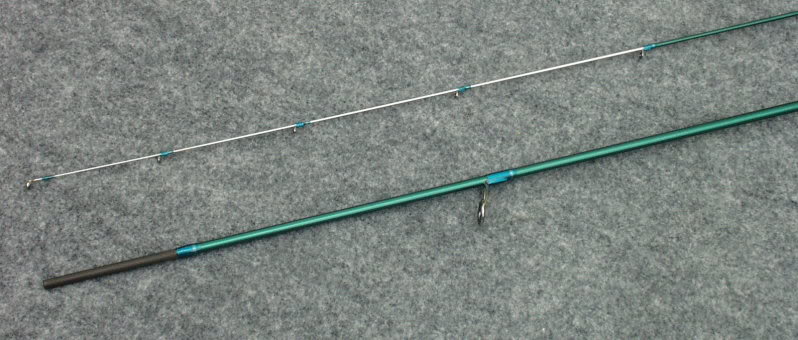

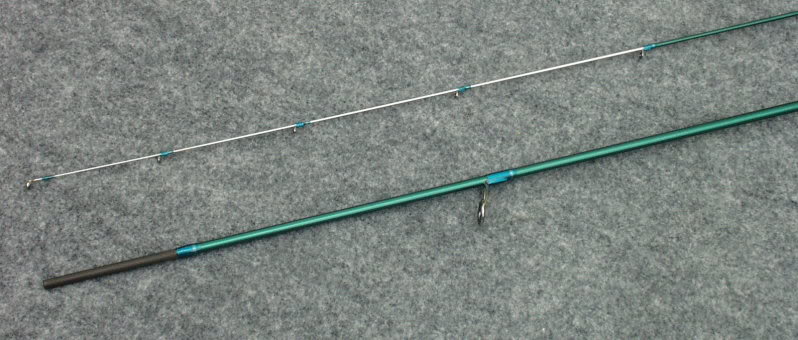

Referenced above, and shown many times, here's one Japanese approach to a superprogressive taper, my 7'9" XUL salt rod.

This rod has a glass core, exposed in the tip, a layer of graphite fibers over 70% of its length, and a weave graphite layer on the butt.

The weave graphite butt is the same idea as a flared butt on a cane rod.

The rod will throw 5g, protect 2-lb test, and has the butt to horse 23" seatrout, which I've done.

When fighting a fish, the angle you're holding the rod defines which portion of the rod is loading, quoting Doc Henshall, "give him the butt"

Victoria is fishing my green Penn 716 on the H-I rod.

Victoria is fishing my green Penn 716 on the H-I rod.